K Series 90 Degree Hollow Shaft Bevel Helical Gear Electric Motor Speed Reducer Reverse Gear Box for Motorcycle

Basic Info.

| Input Power | 8.74-200kw |

| Torque | 32000nm |

| Ratio | 7.14-146 |

| Weight | 100kg |

| Transport Package | Wood Case |

| Specification | KA167 |

| Trademark | HUAKE |

| Origin | China |

| HS Code | 8501320000 |

| Production Capacity | 5000/Year |

Product Description

K series helical bevel speed gearbox reducer | |

Product name | Model K 107 series helical bevel gearbox motor reducer with oil seal overload parallel transmission 90 degree China factory |

Warranty | 1 year |

Applicable Industries | Hotels, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Home Use, Retail,Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company |

Weight (KG) | 50KG |

Customized support | OEM, ODM, OBM |

Gearing Arrangement | Helical |

Output Torque | 3.5-56845N.m |

Input Speed | 0-3000rpm/min |

Output Speed | 0.1-356rpm/min |

Place of Origin | China |

Product name | K Series Parallel Shaft Helical Gear Reducer |

Output Torque | 10-62800N.m |

Output Speed | 750-3000rpm/min |

Input Speed | 0-3000rpm/min |

Input power | 0.12-250kw |

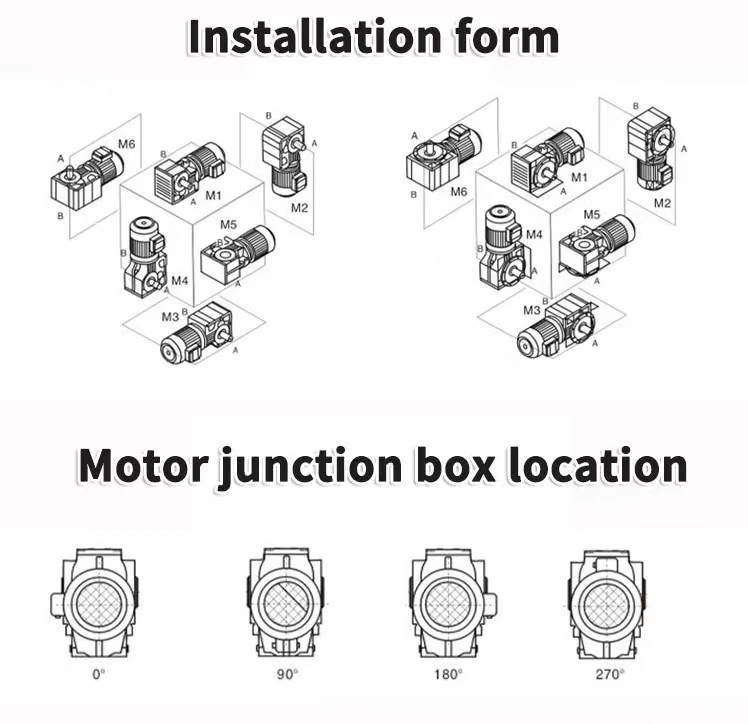

Mounting Position | Foot Mounted. Flange Mounted |

Ratio | 3.77~281.71 |

Gearing Arrangement | Helical |

Reduction ratio | 68 |

Hardness of Tooth Surface | Tooth surface hardness |

Product Description

-K Series Helical Bevel GearboxK series product performanceHigh transmission efficiency, low energy consumption and superior performance. High rigidity cast iron box with ribs; hard-toothed gears are made of high-quality alloy steel, the surface is carburized and quenched and hardened, and the teeth are finely machined, with stable transmission, low noise, large bearing capacity, low temperature rise and long service life.High hardness high grinding accuracyThe gears are made of high-quality alloy carburizing and quenching, the tooth surface hardness is as high as 60±2hrc, and the tooth surface grinding accuracy is as high as 5-6 grades.

Elaborate designFrom the box to the internal gear, it adopts a complete modular structure design, which is suitable for largescale production andflexible selection.

Save powerThe standard reducer model is divided according to the form of decreasing torque. Compared with the traditional equal proportion division, it is more in line with customer requirements and avoids power waste.

Certifications